TMC Mag-NetX Active Magnetic Field Cancellation

- Analog Controller with Digital interface – Analog control of Helmolz-type coils results in more precise real-time cancellation. Digital panel provides simple LCD read-out or PC-based Graphical User Interface (GUI) to the user.

- Flexibility for On-site Tuning – Auto-tuning at start up for typical environments and applications, or adjustable on-site tuning for more challenging environments.

- Real-Time Monitoring – Continuous monitoring with measured fields displayed via the PC-based GUI allows for fine tuning even without relying on microscope image.

Designed for use with any charged-beam instrument, Mag-NetX is an innovative active control system for the compensation of magnetic field fluctuations. With a proprietary analog controller with digital interface to the user, Mag-NetX provides more real-time cancellation with continuous monitoring, while providing the user with a simple built-in LCD, or PC based Graphical user interface (GUI). Continuous monitoring with measured fields displayed via the GUI allows for fine tuning without relying on the microscope image. Alternatively, auto-tuning provides easy start up for typical SEM applications.

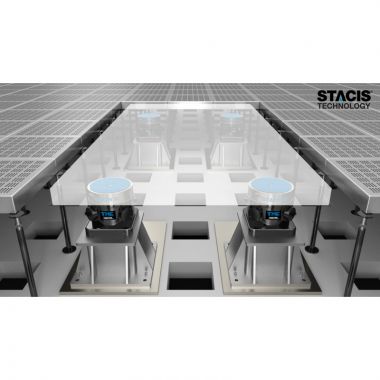

With Helmholtz-type configuration available in a free-standing cage, mounted in tracks on the walls of the room, or direct mounted inside of enclosures, Mag-NetX can be configured to your needs and application.

Challenge TMC with your most demanding requirements for both magnetic field compensation and vibration control for scanning and transmission microscopes, electron beam lithography and ion beam instruments.

Features:

- Helmholtz coil pairs for maximum symmetry and uniformity

- Continuous field cancellation and monitoring

- Several AC and DC cancellation modes available

- 100x field improvement (typical)

- Dynamic, 100 µs response

- Accurate field measurement

- Graphical User Interface with continuous system monitoring and analysis

- Optional feedforward compensation of line frequency and harmonics

- Optional feedforward capability for other inputs

- Optional custom field creation while suppressing disturbance

- Easy to assemble stainless steel cage, in-room wall-mount systems also available

- Cage systems available in any size

- Wall-mount and enclosure mounted configuration include plenum-rated cables

System

| System components | 3-axes orthogonal magnetic sensor, Mag-NetX controller, Helmholtz type coil pairs in cage, enclosure-mounted or wall-mounted configuration |

| Active magnetic field cancellation axes | X, Y, Z |

| Sensor type | Fluxgate type, noise <10 pT/√Hz @ 1 Hz |

| Max. ambient DC field (sensor dependent) | ±70 µT standard up to ±250 µT available |

| Bandwidth (cage and sensor dependent) | DC to 1 kHz typical, up to 2 kHz |

| Dynamic range (cage and frequency dependent) | ±10 µT typ., up to ±100 µT 40 dB typ., 55 dB max. |

| Controlling volume vs. magnetic field flux density | 50 m3 @ 10 µT RMS (depending on cage parameters) 1 m3 @ 50 µT RMS (standard controller is able to cancel Earth magnetic field with special cage construction) 10 m3 @ 50 µT RMS (for canceling Earth’s field in larger volume with special cage and external amplifier) |

| Field reduction ratio at sensor location using typical cage of 36 x 36 x 52 in. / 91 x 91 x 132 cm (L x W x H); |

40 - 50 dB (100x - 300x) typ. in DC 100 Hz 26 dB (20x) typ. in 100-500 Hz |

| Field reduction ratio in a typical electron microscope column volume of 12 x 12 x 24 in. / 30 x 30 x 60 cm using cage of 60 x 60 x 84 in. / 1152 x 152 x 213 cm (L x W x H) |

X, Y: 30 dB (32x) typ. in DC 100 Hz X, Y: 20 dB (10x) typ. in 100-500 Hz Z: 15 dB (5.2x) typ. in DC 100 Hz Z: 10 dB (3x) typ in 100-500 Hz 0 dB @ 1000 Hz |

Controller

| Dimensions | 17 x 9 x 1.75 in. / 43 x 23 x 4.5 cm |

| Operational modes | After power-on:

|

| Types of control tools |

|

| OK LED indicator | green=ok; yellow=warning/error |

| LCD 2x20 symbol display | Show menu and status |

| Bar-LED indicators | Show XYZ real time strength of compensation field |

| 4 directional buttons | for LCD menu navigation |

| USB socket (appears as COM port on PC) | Graphical user interface for advanced tuning/testing, accepts ASCII commands and shows menu |

| Aux. analog inputs (rear DB-37) | Can be used as feedforward or to create custom field |

| GO - NO GO signal relay | Binary, for use as input for protected system |

| Power requirements | 90-240 VAC, 50/60 Hz, 500 VA max. |