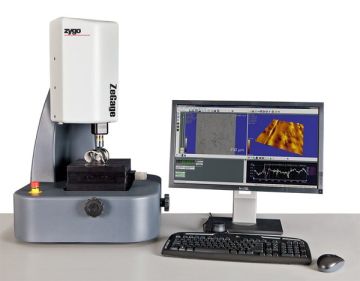

The ZYGO Nexview™ 650 metrology system is an inspection tool for automated measurement of injection molding tooling, PCBs, glass panels and other samples requiring an extended work volume up to 650 x 650 mm. It provides 2D & 3D measurements of a variety of surface features with sub-nanometer vertical precision and sub-micron lateral precision.

Powerful Performance

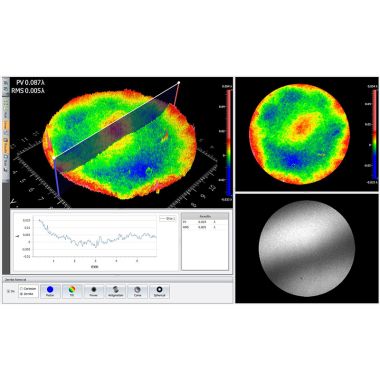

Coherence Scanning Interferometry (CSI) is the measurement technology at the core of the ZYGONexview™ 650 system.

This non-contact technique provides high-precision, and high-value surface metrology benefits including:

- Measures virtually all types of surfaces, from rough to super smooth, including thin films, steep slopes, and large steps.

- Sub-nanometer measurement precision is independent of field magnification

- Gage capable performance - exceptional precision and repeatability for the most demanding production applications.

- SureScan™ vibration tolerance technology - robust operation in virtually any environment.

- Mx™ software enables seamless data exchange with other ZYGO Profilers including ZeGage™ Pro, NewView™ 9000, and Nexview™ NX2.

| System | |

| ZYGO P/N | 6306-0360-04 system with full enclosure6306-0360-05 system with 1/2 height enclosure |

| Measurement Technique | 3D coherence scanning interferometry, SureScan™ technology |

| Scanner | Precision Piezo drive with Closed loopcapacitance gauge control andcrash protection |

| Objectives | 1.0X – 100X magnification; Standard and long working distance; See the Nexview & NewView 9000 Series Objective Chart for more details |

| Objective Mounting Options | Single objective dovetail Manual Encoded 4-position turret Motorized 4-position turret |

| Optical Zoom | Motorized 3-position encoded zoom • 0.5X, 1.0X, 2.0X included • 0.75X, 1.5X optional |

| Field of View | Objective and zoom selectable from 0.04 x 0.04 mm to 17.49 x 17.49 mm; Integrated field stitching for larger areas |

| Illuminator | Proprietary solid-state white light source with software-selectable field stop, aperture stop and spectral filters |

| Measurement Array | Selectable 1600 x 1200, 1000 x 1000,1000 x 600, 1000 x 200 |

| Part Viewing | Selectable Monochrome imaging with available fringe-free viewing mode |

| Focus | Motorized manual or auto focus with Part Finder and Smart Setup Technology |

| Z-Drive (Focus) Stage | 150 mm range with 0.1 μm resolution |

| Part Stage | Encoded linear motor drive with 650 x 650 mm XY travel range |

| Stage Configuration |

Split axis gantry style; X-stage translates Head; Y-stage translates the sample |

| Sample Holder | Custom vacuum sample holders up to 650 x 650 mm available |

| System Controller | i7 class PC with 1080P display |

| Software | ZYGO Mx software running under Microsoft Windows 10 (64-bit) |

| Physical | |

| Dimensions (HWD) |

System with enclosure: 166 x 140 x 164 cm |

| Weight | System:1830 kg System with enclosure: 1955 kg |

| Utility Requirements | |

| Input Voltage | 100 to 240 VAC, 50/60 Hz |

| Compressed Air for isolation | 4.1 to 5.5 bar (60 to 80 psi); dry and filtered; 1/4 in. input |

| Vacuum | Optional from a customer supplied source, based on part stage requirements |

| Performance | |

| Vertical Scan Range | 150 μm with precision Piezo drive; 20 mm with extended scan |

| Surface Topography Repeatability(1) | 0.12 nm |

| Repeatability of RMS(2) | 0.01 nm |

| Optical Lateral Resolution(3) | 0.34 μm (100X objective) |

| Spatial Sampling | 0.04 μm (100X objective 2X zoom) |

| Maximum Data Scan Speed(4) |

53 μm/sec @ 1600 x 1200 69 μm/sec @ 1000 x 1000 107 μm/sec @ 1000 x 600 171 μm/sec @ 1000 x 200 |

| Step Height Repeatability(5) | 0.1% |

| Step Height Accuracy(6) | 0.3% |

| Test Part Characteristics | |

| Material | Opaque, transparent, coated, uncoated, specular, rough |

| Maximum Sample Height |

260 mm under X axis Crossbeam 329 mm under typ. objective focus |

| Maximum Surface Slope | 55° – smooth part @ 100X 85° – scattering surface |

| Sample Reflectivity | 0.05% - 100% |

| Environmental Requirements | |

| Temperature | 15 to 30°C with rate of change <1.0°C per 15 min |

| Humidity | 5 to 95% relative, noncondensing |

| Vibration Isolation | Included and required for vibration in the range of 1 Hz to 120 Hz |

| Vibration Criterion | VC-C or better |

| Acoustic Criterion | NC30 or better |

Footnotes:

Performance specifications under laboratory conditions using standard specimens, according to ISO 25178-601, 25178-604 and 5436-1.

(1) Surface Topography Repeatability for CSI mode, 1-sec acquisition, full FOV with 3x3 median filter, in a laboratory environment.

(2) Repeatability of the RMS surface roughness parameter Sq, under the same conditions as for (1). Note that the repeatability of the Sq is sometimes referred to informally as "vertical resolution."

(3) Lateral Resolution=Sparrow criterion, objective dependent.

(4) Data scan speed depends on the measurement array and data acquisition mode.

(5) 1- Step height repeatability verified using 1.8 μm and 24 μm ZYGO certified step height standards.

(6) Instrument contribution to uncertainty for step height measurements using the piezo drive.

| Photo | Product | Price | |

|---|---|---|---|

| Zygo Nexview™ NX2 | > | |

| Zygo Nexview™ | > | |

| Zygo NewView™ 9000 | > | |

| Zygo Compass™ 2 | > | |

| Zygo Mx™ for Optical Profilers | > |