The synthetic fluoropolymer of tetrafluoroethylene AKA Polytetrafluoroethylene (PTFE) and its analogues are strongly hydrophobic and having low surface energies of less than 18 dyn/cm are perhaps best-known for their non-stick properties. This low surface energy along with PTFE’s high electrical insulating properties can make sputter coating with noble metals prior to SEM a real challenge.

Not anymore.

Some of the traditional compromises around this problem are:-

- Coat with a very thick layer 20 nm Gold - this will mask all the finer detail of the surface structure.

- Coat with a thin sub 1 nm layer of Chromium to act as a seed layer for successive precious metal layer - not everyone has access to the high vacuum required for chromium sputter coating which is also very prone to surface oxidation.

- Plasma treat the surface to improve the surface reactivity and thus more receptive to precious metal coating - long plasma treatment times are required in order to make significant changes the surface reactivity on PTFE which will result in surface morphology modifications rendering high magnification studies useless.

The modern way is to use the Innovative LuxorPt sputter coater for such challenging samples where the compromise to image quality is no longer an issue.

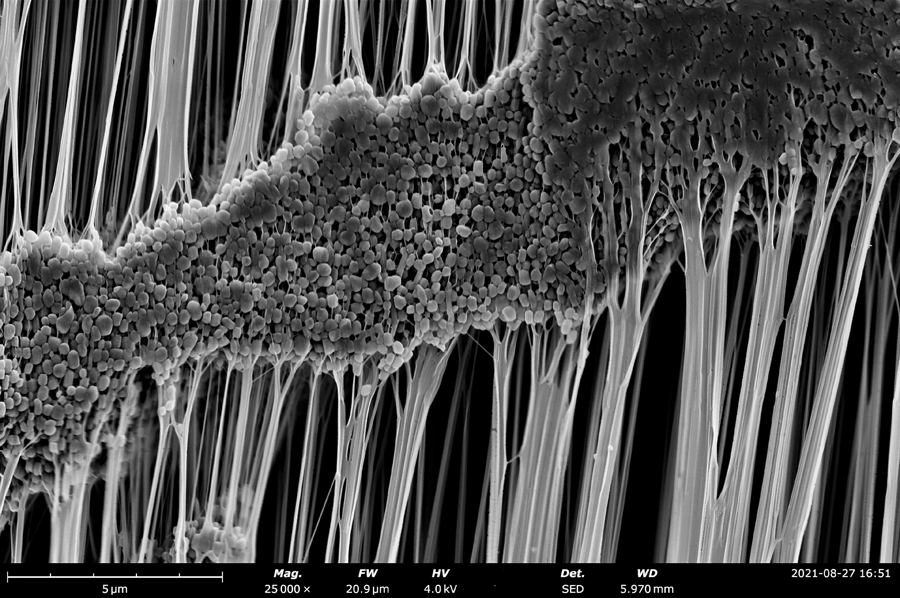

The micrograph shows a sample of PTFE tape coated with only 2nm of platinum using the LuxorPt sputter coater. There is no surface charging due to the coaters excellent covering power and the fine structural detail is maintained with only2nm of platinum required.

LuxorPt - Delivering Innovation, Quality, Performance and Economy

To speak with one of our Sales & Applications Engineers please call 01582 764334 or click here to email.

Lambda Photometrics is the leading UK Distributor of Characterisation, Measurement and Analysis solutions with particular expertise in Instrumentation, Laser and Light based products, Optics, Electro-optic Testing, Spectroscopy, Machine Vision, Optical Metrology, Fibre Optics, Microscopy and Pulsed Xenon Light Systems.