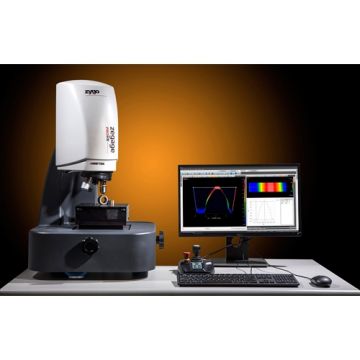

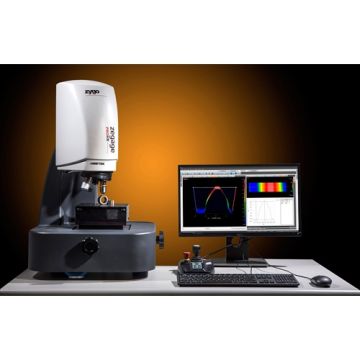

SmartSetup is a feature implemented on Zygo’s latest generation of 3D optical profilers to address four important setup tasks:

- 1. Find the part

- 2. Set the appropriate light level

- 3. Set the appropriate scan range

- 4. Get the first measurement

Finding the part (i.e. fringes) can be time-consuming for experienced as well as new users. It is often relatively easy to find fringes at higher magnifications like 10x on a rough surface, but it can be very difficult to search at low magnification like 1x on smooth surfaces such as glass or silicon. The lack of surface features, coupled with a large range across which any features will appear in focus, means there is little visual information to help the user locate, slow down and fix onto the focus position. It can be exactly like searching for a needle in a haystack!

Zygo developed SmartSetup to carry out these four tasks quickly and robustly from very smooth to very rough samples, and on samples with extreme surface tilts. It is activated with a single button press, and typically finishes and displays a data map within a minute.

SmartSetup gives the following advantages to users:

- Even in optimal conditions for manual control such as high magnification with rough surfaces, SmartSetup is faster than an expert operator and will lead to increased productivity.

- In difficult conditions such as low magnification with smooth surfaces, SmartSetup will still locate, set up and measure the surface within a minute. Experienced operators can often take a few minutes to do the same manually.

- The burden on training and practice is reduced because SmartSetup automates the exact tasks where expertise makes the biggest productivity difference.

- The more varied the parts and surfaces encountered, the more the productivity will be enhanced. This makes the feature especially useful in R&D and general metrology applications.

For further information, application support, demo or quotation requests please contact us on 01582 764334 or click here to email.